Drummond Biles

Mechanical Engineering PhD Candidate | University of New Hampshire

Click to view a pdf of my senior lab pdf report

Senior Lab Project

In the fall semester of the mechanical engineering curriculum all students take a senior lab class called experimental measurements and control. The final project for the class is to create your own experiment using some of the sensors and techniques discussed during the semester. I utilized this project to create an experiment around my senior design project.

2013 YFZ450R engine

My senior design project was the Formula SAE design competition where I worked with 14 other engineering students to design and build a small scale formula one style race car. As part of this I was the controls captain which put me in charge of determining all the ways that the driver would interact with the car. One major design goal we had was to implement electronic shifting in the car to improve shift time and driveability of the car.

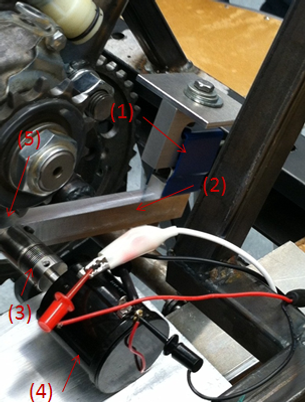

The first step in designing this system was understanding what it would take to shift through the different gears in the transmission. The motor that we would be using was a 2013 YFZ405R single cyclinder engine out of a quad bike as pictured to the right. This motor has an internal transmission, so after mounting it to an engine stand we were able to outfit the shift lever with a simple shift arm and sensors are pictured below.

SolidWorks models of the 2013 FSAE car

The picture to the left shows the experimental setup that was used. A shift arm (2) of known length was attached to the shift knob (5) with a force transducer (1) mounted at the end. A potentiometer (4) was then attached to the shift knob as well, through a flexible coupling (3). Shifting was performed by pressing down on the force transducer until a shift was completed. We then got time resolved force and position from two sensors.

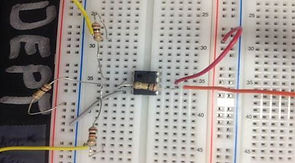

Amplification circuit

Force Transducer

Potentiometer

Side view of shift linkage with force transducer attached

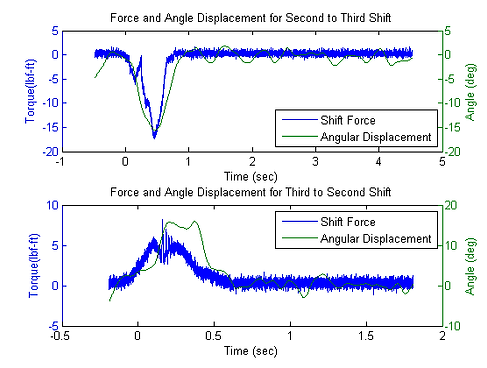

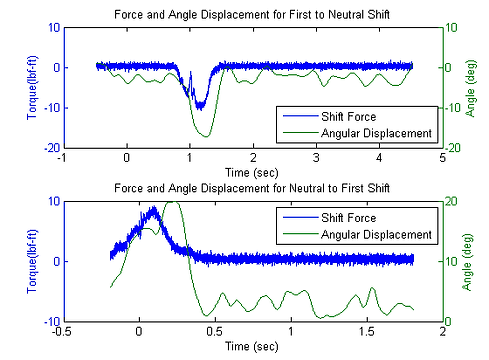

The left displays some of the resulting torque profiles for shifting the motor. Multiple trials were down the entire range of gears and it was concluded that a motor would need to be able to supply 17.85 lbs/inch for an up shift and 15 lbs/inch for a down shift. This then allowed us to begin sourcing an electric motor which could shift the transmission. The final report for this experimental study can be found at the bottom of the page.